Decentralisation in supply chains and ESG

Resilient supply chains and ESG practices have more in common than one might think. Supply chains are becoming more fragile, as firms are ever more dependent on each other to deliver value to their customers. In parallel, customers and regulators are demanding more from companies in terms of ESG performance and reporting. For most companies these ESG improvements need to be made in their supply chains.

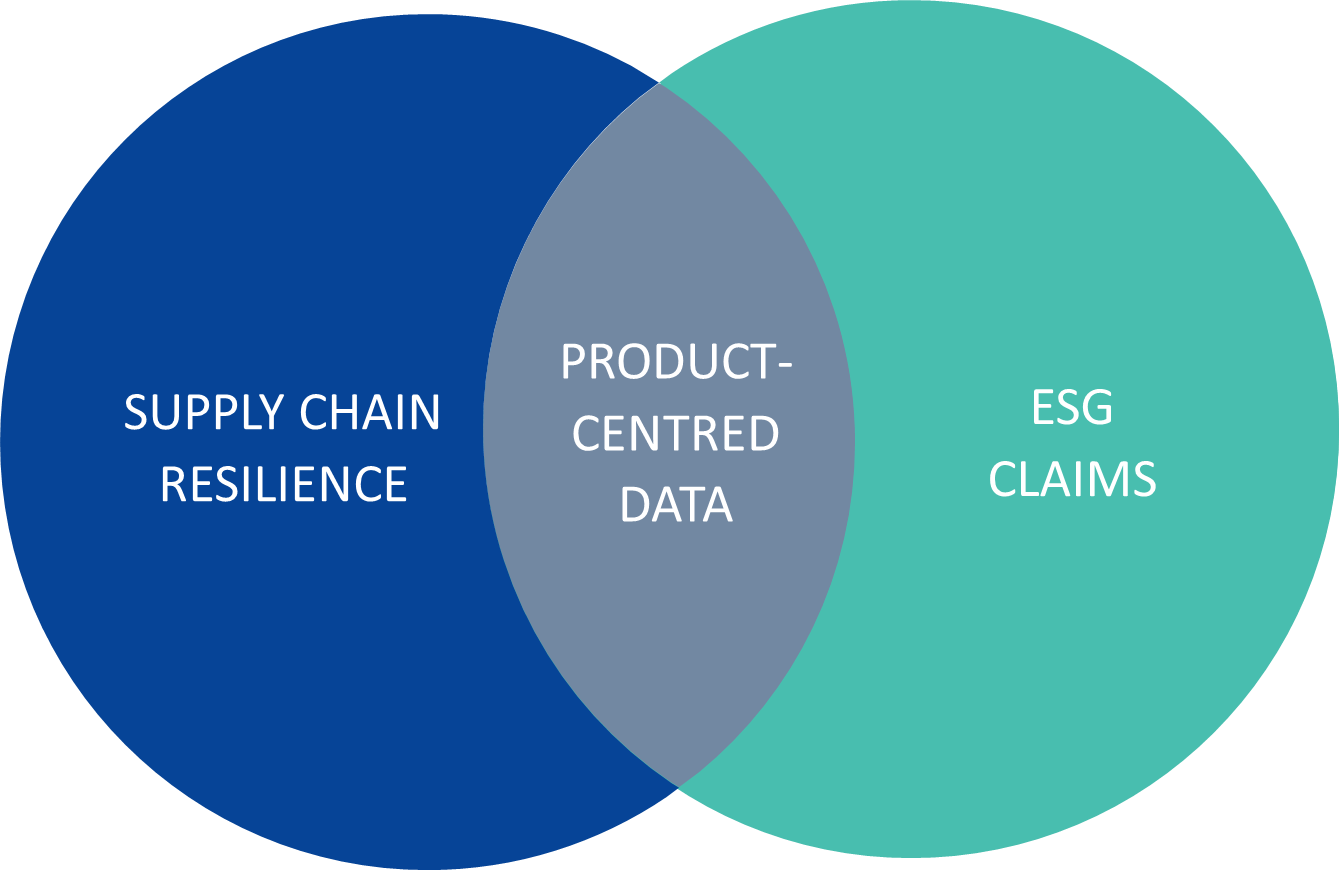

In this paper, we discuss both seemingly disconnected challenges and show that product-centred data offers a surprising yet effective solution to both improve supply chain resilience and execute ESG strategies.

Figure 1- Supply chain resilience and credible ESG claims can be achieved through a product-centred data trail

We will use grey-ink to show how ParkaCo – a fictional jacket company based on real experience – suffered from both seemingly disconnected challenges and will show that product-centred data established through the decentralised operating model, offers an effective solution to both challenges.

1. Supply chain resilience

Products come to life through a complex supply chain of producers, transporters, wholesalers, distributors and retailers. Data relevant to a product is locked in the databases of each individual organisation involved. Whenever companies wish to gather critical data about the product– e.g. supply chain bottlenecks, dwell times or product location — they need to go to their supply chain partners to collect the necessary information.

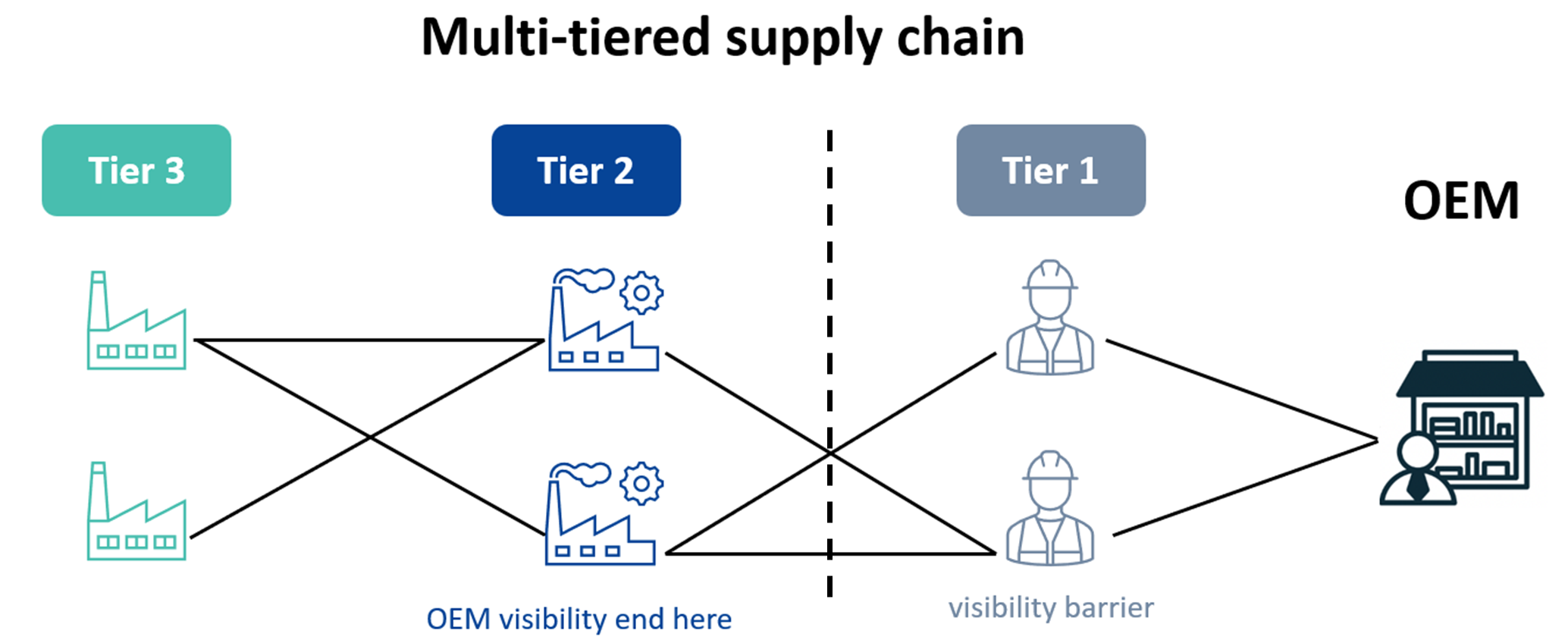

This is a time-intensive and lengthy process. It’s often hard to establish since most suppliers several tiers down the supply chain (“the suppliers of suppliers”) are invisible and not known.[1] Although most companies have some visibility into their supply chain, creating end-to-end supply chain visibility greatly enhances supply chain resilience without overspending on “just-in-case inventory”. Let us expand.

In response to supply chain shocks in recent years, such as the Suez canal obstruction, Covid-19 crisis, geopolitical conflict and chip shortages, supply chain resilience has gotten increased attention. Many companies have increased their inventory holdings and resorted to dual- and near sourcing their materials. Yet, without sufficient supply chain visibility, the efficacy of such measures is difficult to establish. For example, when companies look to dual-sourcing products, but do not have full visibility into their supply chain, they may inadvertently still be dependent on the same raw material provider, staying exposed to the same supply chain shocks.

Having better and more real-time insight into a supply chain would greatly enhance resilience. To truly achieve that, we propose a new perspective in paragraph 3.

Figure 2 – Supplier visibility in a multi-tiered supply chain

We sat down with Joan, Chief Supply Chain Officer (CSCO) at ParkaCo. She explains that her supply chain, like many others in the apparel industry, starts with fibre producers: farmers that grow natural fibres like cotton and/or industrials which produce petroleum-based artificial fibres like polyester. The fibres are then passed on to yarn manufacturers who create the yarn that fabric manufacturers use for industrial weaving to create different dimensions of fabric. Even before reaching apparel manufacturers, who stitch the fabrics into jackets, the materials have already passed through several hands.

Every stage of her supply chain involves a multitude of companies. As the jacket travels through the supply chain, it creates important data that would help Joan and ParkaCo. Many data points are available, but they are stuck in the silos of the ERP systems, e-mail or even paper trails of the individual companies handling the jacket.

Although Joan has previously initiated efforts to centrally gather data throughout the supply chain, many supply chain partners are reluctant to hand over information to a database that is controlled by ParkaCo.

Joan has limited information about the supply chain processes several tiers down. It is, for instance, hard to pinpoint where in the supply chain shippings go missing or to combat counterfeit products. Small supply disruptions are a common occurrence (part of the “cost of doing business”), and effectively estimating the impact of these delays on required inventory is difficult. This leads to ParkaCo overstocking, generating textile waste and unnecessary additional costs. As margins are slim in the apparels industry and the turnaround of fashion cycles is short and seasonal (often six months or less), a more efficient supply chain is in the interest of all partners.

Gaining better supply chain visibility would be an important starting point in helping Joan further optimise the supply chain and reduce (in)efficiencies and waste.

2. ESG claims and compliance

The lack of real and real-time-insight into supply chain data is also a problem for ESG claims and compliance.

Companies are held responsible for the ESG practices within their value chain[2] – customers, regulators and the general public all demand responsible ESG practices from businesses. Increasingly, these demands are laid down in legislation. For example, the Corporate Sustainability Reporting Directive (CSRD) in Europe and SEC climate disclosure rules in the US require a subset of companies to disclose ESG practices within their supply chain. But it’s not only compliance with regulation, there is also a growing number of court cases over greenwashing claims.[3]

So it is in any companies interest to substantiate their ESG claims from a compliance as well as a reputational perspective. And having insight into their supply chain – both up-and downstream- is becoming crucial. Being able to make ESG claims based on real and real-time insights throughout a

value chain is a competitive advantage as companies further downstream prefer suppliers that deliver products with high-integrity ESG claims.

Today most companies resort to expensive “single-use” supply chain compliance audits[4], which at best, gives them a snapshot of only one part of their supply chains to work with. These audits are expensive, lengthy (lasting six months to a year), and do not provide the company with any long-term internal capabilities. They would benefit from a more scalable, cost-effective, and future-proof solution that grants end-to end insight into their complex supply chains. In the next paragraph we propose a new perspective to achieve exactly that.

Our conversation with Joan piques the interest of Alex, ParkaCo’s Chief Sustainability Officer (CSO). The company’s CEO has tasked Alex with a key mission: to comply with the EU Corporate Sustainability Reporting Directive (CSRD) and to promise a “net-zero jacket” to their customers.

As part of this effort, Alex also needs to collect, disclose and address potential human rights violations, corruption, or bribery in his supply chain as well as collect information on GHG emissions and climate-related risks[5]. Competitors of the company have recently been accused of selling fast fashion as organic cotton and Alex wants to prove that no false claims are made about ParkaCo’s products. Much of the information Alex wants to gather is required by regulators[6] and his CEO. However, Alex runs into the same problem as Joan, most suppliers are unwilling to submit sensitive data to a database that is owned by ParkaCo and currently information is collected inconsistently, in incompatible and error-prone formats such as Excel spreadsheets, e-mails, differing ERP systems or even a paper trail.

While Alex and Joan can often be at odds with each other, they both need a solution here that requires insight into the supply chain. They need to create a full data trail for the jacket and gain insight into their suppliers’ suppliers. Because ParkCo’s supply chain is expansive, complex, and more ESG regulations are upcoming[7], an expensive ESG audit will not do the trick – what they need is a more permanent and scalable solution.

3. A new perspective: centering data around the product

What if we were able to connect all data that is already there and liberate it from its silos? This would greatly enhance transparency and thus insight into a supply chain.

But while everybody wants transparency, nobody wants to be transparent; even revealing who one’s supplier is, is commercially sensitive information. Even if we solve that, how do we make sure the data provided can be trusted?

This is why we propose a new perspective: anchoring digital data to a physical product end-to-end in a supply chain in a decentralised way. Making use of digital technologies that are privacy-enhancing, tamper-proof and have built-in incentives, without the need for a single company to hold all the data. This ensures the solution is scalable, guarantees the integrity of data, has built-in incentives for data-sharing and can deliver proofs without revealing the underlying raw data.

We call this new perspective the Decentralised Operating Model.

At the core of the decentralised operating model is a product (e.g. the jacket) and the components it is made of. The product has a Digital Passport which contains (pointers to) all relevant data associated with the product. While the product moves through a supply chain, more data is added. The type of data can vary and is not necessarily always the raw data but can also be so-called verifiable credentials (VCs). Access to the data can be context or role-based so that we can achieve selective disclosure. Most data will remain in the ERP systems where they are now, but they are anchored to a blockchain to guarantee its immutability; in that way anyone who reads the data can be assured that the data has not been tampered with.

And while the Digital Product Passport is the visible consequence of our decentralised operating model, it is much more than that. The Decentralised Operating Model should fit seamlessly into existing processes and should be minimally invasive. The system driving the Digital Product Passport should be embedded seamlessly in the business: processes, policies/contracts, technology stack, performance management, people & capability building, and within its organisational structures.

This decentralised operating model is unique because it is not led or controlled by a single entity (an individual, company, or institution) but by a series of collectively determined design choices written into the architecture of the system itself. This can be done through a consortium but could very well be completely embedded in the solution as well.

The Decentralised Operating Model and its deployed Digital Product Passport are highly scalable as it is a plug-and-play solution from a technical point of view but also in terms of process and governance. No need for anyone who joins in to get into lengthy contracts with a vendor. It allows companies access to the real-time location of their products, embedding accountability[8] into their supply chain and immutable ESG information. But the options do not stop there, other information such as authentication (or anti-counterfeiting) becomes possible and brands can easily add digital services to their physical products.

The benefits of product-centred data

- confidential and/or sensitive data stays private

- internal capabilities for esg compliance (no expensive single-use audits)

- a collective infrastructure for supply chain information without centralised control

- supply chain accountability and an effective mechanism for incentivizing esg practices

- enhanced supply chain visibility and management information based on a tamper-proof data trail

Figure 3 – A decentralised product passport is build and enriched

The decentralised operating model can address both Joan and Alex’s headaches, by collecting data associated with the jacket across different nodes of the supply chain. Rather than leaving data behind in various supply chain partner databases, the jacket gets a QR code at the start of the manufacturing process, and each member of the supply chain adds (and receives) jacket-related (meta)data. The QR code is scanned by each intermediary, building an end-to-end and real-time provenance trail. Monitoring equipment is added to shipments minimising the risks of losing shipments as well as showing a comprehensive map of dwell times, and the impact of supply chain disruptions. Also ‘trade finance’ will become easier once we have better insight into all tiers of a supply chain.

ParkaCo can calculate the emissions associated with the production and transport of the jacket and reduce, avoid, and compensate for their emissions. Using the same foundation, the company can not only gain the insights needed for CSRD compliance but it has also laid the foundation for compliance with upcoming regulations such as the Carbon Border Adjustment Mechanism[9] and the Green Claims Directive[10]. Using supply chain insights the company can inventarise potential waste and recycling opportunities to limit its total footprint.

All data is kept in a decentralised manner, ensuring that it can not be tampered with along the way, More importantly, through the decentralised operating model, no single party owns the shared audit trail which helps Joan and Alex to convince their partners to participate. The participating intermediaries can work with ParkaCo to define what information to share and what to keep confidential, this comfort is further enhanced through the use of technologies that enhance data sovereignty such as Zero-Knowledge Proofs.

Joan and Alex are also excited about the possibility of making certain data visible to trusted supply chain partners. The visibility allows for Joan to cooperate with her suppliers for regulatory compliance or for Alex to set up an incentive scheme for suppliers to become compliant with ParkaCo’s net-zero objectives.

4. Our Proven Approach

Our approach to building decentralised operating models with our clients follows a four-step process: Ambition, Design, Development and Adoption. We ensure that our clients are clear about the purpose and the main design of their operating model, before diving into the development or adoption of a specific technology solution, or joining an existing consortium.

Figure 4 – Our four-step approach to creating and growing decentralised operating models

This process is designed to help our clients overcome the main obstacles that companies like ParkaCo may face, along each step of their decentralisation journey. Adoption of decentralised systems is a multi-generational process, so companies are likely to go through this four-step process several times iteratively.

- Ambition

The first step is always to create executive-level consensus around the long-term vision and purpose of the operating model. For ParkaCo this would take the shape of a Leadership Team workshop around defining a common goal for the project: for example, improve supply chain visibility and collaboration with trusted partners. With this ambition defined, each business function would work with us to map the “as-is” situation and the context we are operating in: as-is mapping, information systems mapping, stakeholder mapping, legal & regulatory landscape, past lessons learned, etc.

ParkaCo’s ambitions will grow iteratively with the maturity of its blockchain use-cases, so the ambition will occasionally be revisited and adjusted.

- Design Operating Model

After defining the ambition, we work on defining the specific decentralised operating model together. Members of Joan and Alex’s teams, key stakeholders from other teams, as well as partners from partner organisations, will work to adopt business/organisational, technological, and legal perspectives.

ParkaCo approaches several key partners and discusses their ambition with them. The partners recognize the importance of the project, both for their internal compliance goals and for the improvement of their services, therefore they are keen to participate. With this small coalition the partners are ready to move to the next stage.

- Deployment of the blockchain use-case(s)

In parallel to the design of the decentralised operating model is the agile deployment of the blockchain tools to power this operating model. Often deployment of these tools can be built upon existing open source or white-label solutions.

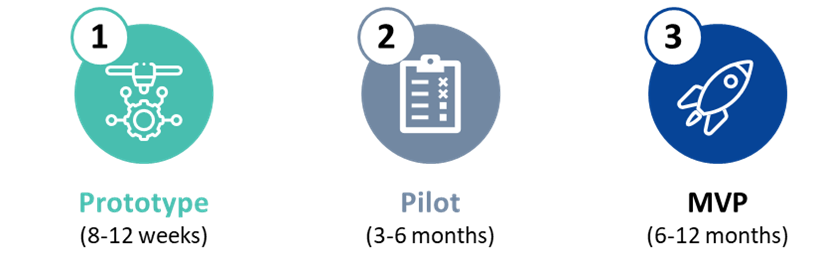

Joan and Alex from ParkaCo will need to make important technology choices, such as which blockchain solutions to make, buy or partner with. Together with the coalition of key partners we jointly develop and refine a first prototype.

Figure 5 – A schematic overview of our solution development process

In a bit less than six months, ParkaCo and several key suppliers have further refined technical requirements and needs for a proof-of-concept.

Months later, the prototype is further developed into a pilot which is further refined. After good initial results ParkaCo is ready for an initial launch and more partners are involved. The Minimum Viable Product (MVP) is jointly developed and launched.

The launch leads to further feedback. Some of which is immediately addressed, other major changes are shortlisted for the development of the fully-functional tool in the adoption phase.

- Adoption

A Decentralised Operating Model requires a different roll-out strategy which meets the diverse information, learning, and Change-related needs of every person and organisation affected by the change. Successful adoption is inextricably linked to a proper understanding of the industry dynamics, incentives and existing legacy systems.

Decentralised solutions will achieve desired adoption if there is:

- Clear and sustained communication of expectations and results to executive-level stakeholders

- Communication with supply chain partners and other users of blockchain tools, about the benefits of them participating

- Effective incentives for intermediaries to change their processes and ways of working in favour of the new decentralised tools

- Understanding of the legal and regulatory landscape subject to the implementation of the use-cases

- Accurate estimation for the cost of execution, including in particular the cost for coalition-building, training and onboarding.

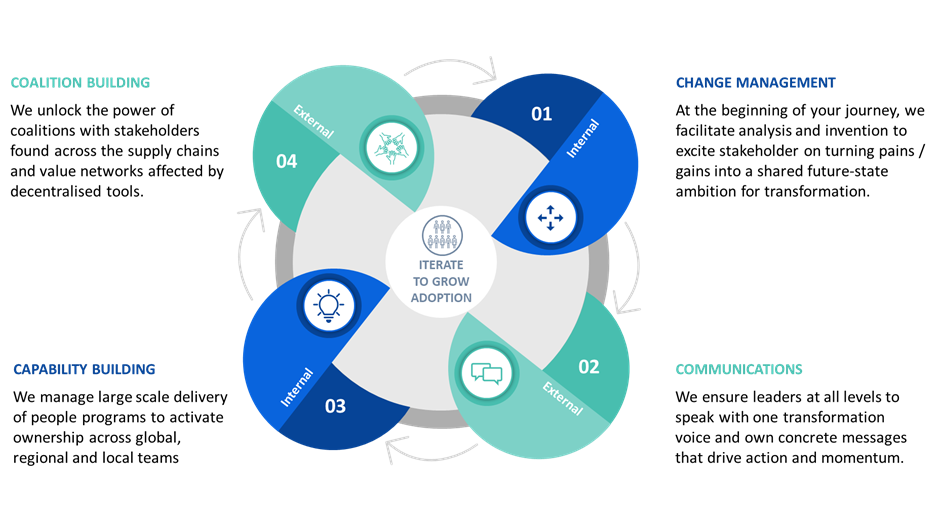

Our 4Cs approach to adoption (see below) helps ensure that every step of the way, from building Executive-level consensus at ParkaCo to creating momentum across the jacket’s vast supply chain, adoption remains the priority. These four activities (Change Management, Communications, Capability Building, and Coalition Building) are run concurrently with the design and deployment phases. They will therefore iterate and evolve along with the ambitions, design and current deployment of the decentralised operating model.

Figure 6 – the 4Cs of decentralised operating model adoption

About

The combination of Warren Brandeis and OXYGY brings together a deep understanding of decentralised technologies and their applications in sustainability and supply chains with leadership in digital transformation, and systemic change. We are unique in our experience building adoption for large-scale systems and emerging digital solutions such as blockchain. Through our joint offering we can help you implement a transformative solution combining organisational, technical and legal/regulatory expertise (with Bird & Bird). Combining vision with pragmatism this approach does not require overhauling entire enterprise systems in the short run, but realises meaningful change in the long run.

[1] A study by MIT has indicated that 81% of companies do not have full supply chain visibility and 54% of companies have no supply chain visibility at all. https://mitsloan.mit.edu/ideas-made-to-matter/supply-chain-visibility-boosts-consumer-trust-and-even-sales

[2] Some high-level examples are controversies around Nike and H&M.

[3] Recently, in Europe, the standards around ESG claims are in the process of being formalised into the Green Claims Directive.

[4] These audits are done to solve complex supply chain issues and/or to comply with sustainability laws and regulations such as the CSDD, CSRD, the Climate Corporate Data Accountability Act (in EU) and the New York’s Fashion Sustainability and Social Accountability Act and Uyghur Forced Labor Prevention Act.

[5] https://finance.ec.europa.eu/capital-markets-union-and-financial-markets/company-reporting-and-auditing /company-reporting/corporate-sustainability-reporting_en

[6] For example, the New York’s Fashion Sustainability and Social Accountability Act would require

[you 7] To name but a few: the Green Claims Directive, Green Public Procurement, Waste Shipment

[8] Accountability embeds the tracking of promises (legal commitments) into an information infrastructure. Delivery on time, in a given quantity and quality, with defined product characteristics and features. Accountability across value chains involves establishing where exactly a promise has been broken.

[9] At the time of this writing the CBAM does not apply to the fashion industry yet, but is being phased in for other carbon-intensive industries.

[10] At the time of this writing the Green Claims Directive has been adopted and will enter into force soon. https://www.consilium.europa.eu/en/press/press-releases/2024/02/20/consumer-rights-final-approval-for- the-directive-to-empower-consumers-for-the-green-transition/